KR8 Inverted Front End Installation Guide

FITMENT: 2009 and Up FLHR ROAD KING, FLHT ELECTRA GLIDE, FLTR ROAD GLIDE AND FLHX STREET GLIDE

KRAUS Motor Company designs, engineers, tests, and manufactures performance suspension and braking systems for Harley-Davidson™ motorcycles designed to deliver improved road feel in real world punishing riding conditions. KRAUS Sport Touring Packages come complete with a fork stem and all necessary stock hardware and parts to bolt a KRAUS Inverted Front Suspension Package up to your bike. These instructions are meant to be an overview, a guide for the experienced technician. If you do not have prior experience or training installing motorcycle suspension componentry, we strongly recommend that you consider hiring a qualified, experienced technician to install this KRAUS Performance package for you.

About Finishes: Like most finishes, anodizing is delicate and can be scratched. Extra care should be taken during installation and cleaning of all of our parts. Although we use a high grade type 2 anodizing that has UV resistance, anodizing is an organic process/ substance and can fade with excessive sun exposure or be stained with chemicals and cleaners.

Disclaimers:

- This installation may require cutting or drilling factory components. Please read instructions carefully before beginning installation.

- Will require aftermarket 108mm radial brake calipers.

- May Require new front brake lines depending on your choice of caliper.

- Using your factory Nacelle may require modifications such as drilling/cutting, Kraus recommends finding an alternative to the factory nacelle or removing it all together.

- KR8 instructions will begin from the point where the front end of the bike is completely disassembled; front wheel, forks, and trees MUST be removed.

PROJECT DETAILS:

- Time required: One full day for a Sr. Tech.

- Existing Componentry and OEM Fork Set Removal: 1.5 hours

- KRAUS Performance Package install: 4.5 hours

- Validation and Road Test: 1 hour

Tools Required

- Torque wrench

- Allen Key Set: T-handle/ball and regular SAE & Metric

- Socket Set: SAE & Metric

- 2 non-marring wedges

- Bearing Press

STEP 1 - REMOVE YOUR OEM PARTS:

- Fairing

- Dash Panel

- Key Switch

- Front Forks

- Triple Tree…AND…any associated bodywork or accessories.

Remember: Take your time removing all of the controls and bodywork. We recommend covering your tank.

Note: We strongly recommend replacing your neck bearings with new bearings.

STEP 2 - BEGIN INSTALLATION:

FORK PREPERATION:

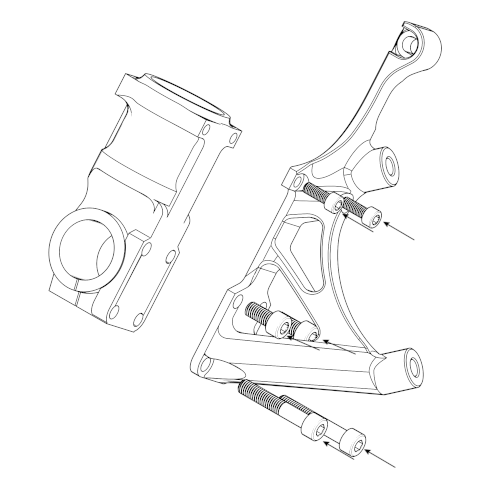

- Install Brake Caliper mounts onto fork. (See fig. 1)

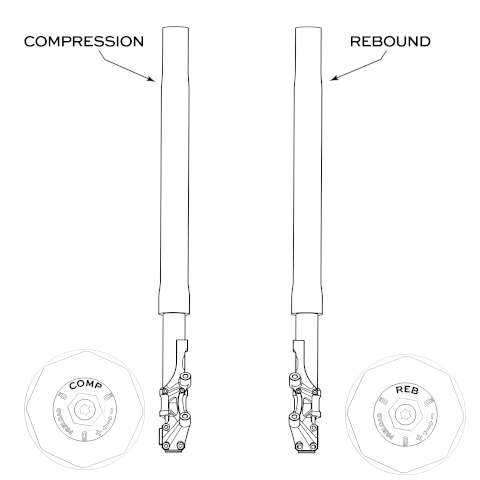

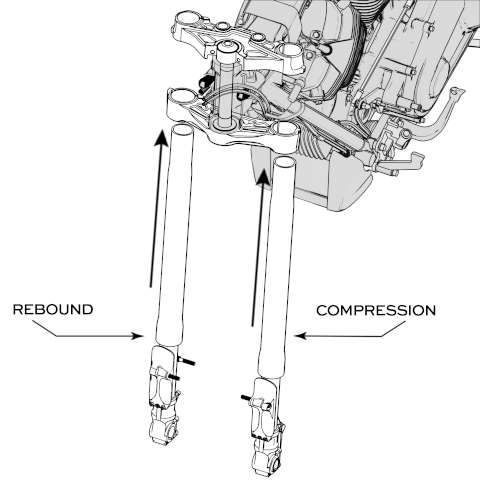

NOTE: Rebound Fork is intended to be installed on right side of bike while Compression fork is to be installed on the Left, viewed from the seated position of the bike.

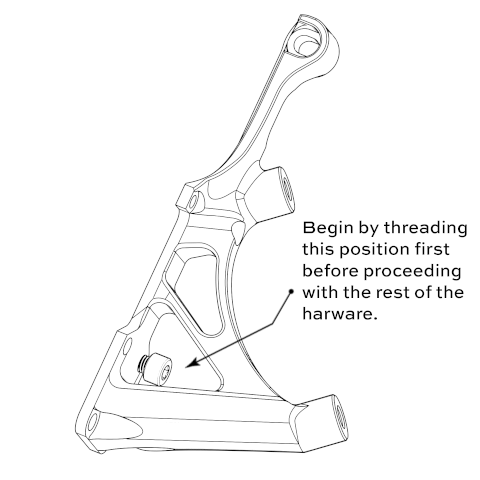

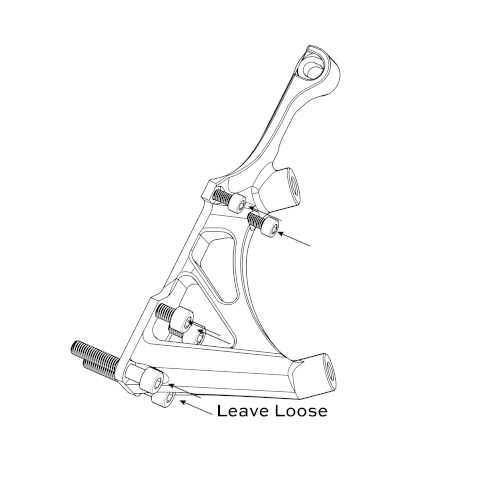

Compression fork has “COM” inscribed on top cap; Rebound has “REB” inscribed on top cap. (See fig. 2) - Using supplied hardware from fork component box, begin with the screw position on inner middle hole closest to wheel (See fig. 3), torque to spec, (Upper M6 Screws; 7Nm/62in-lbs), (Lower M8 Screws; 19Nm/170in-lbs). Leave axle screws loose. (See fig. 4)

- Install fork guards (M5 Screws, 4Nm/35in-lbs). (See fig. 5)

Torque Specs:

- Upper M6 Screws: 7Nm/62in-lbs.

- Lower M8 Screws: 19Nm/170in-lbs.

- M5 Screws: 4Nm/35in-lbs.

Fig. 1

Fig. 2

Fig. 3

Fig. 4

Fig. 5

INSTALLATION OF TRIPLE TREES:

- Clean/inspect races, bearings & dust shields then grease your bike’s neck bearings for install.

- Install/slide the lower neck bearing dust shield followed by the lower neck bearing onto stem. Press them carefully onto the stem attached to the lower triple tree.

- Press the lower bearing down the stem towards the dust shield until firmly seated at the stem’s base. The bearing should spin freely.

- Apply the specified and appropriate grease to the upper and lower neck bearing races.

- Carefully slide bottom triple tree and stem up through frame neck.

- Carefully place the top neck bearing onto the stem.

- Gently press the upper bearing down the stem towards the fork neck until firmly seated on the top bearing race. The bearing should spin freely. Place top dust shield over the top neck bearing.

- Thread on Yoke Nut until there is good bearing feel. (See fig. 6)

- Slightly loosen yoke nut until no friction is felt.

- Install bars and risers onto top triple tree.

- Install the top triple tree onto yoke nut, ensure that it is seated properly onto the bearing dust shield. Ensure the triple tree moves freely from side to side.

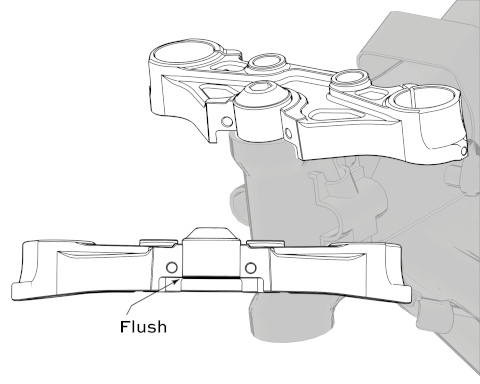

- Ensure top nut is flush with bottom of tree. (See fig. 7)

- Install top nut clamp onto top tree. Tighten screws until lightly seated, so fall away can be set later. (See fig. 8)

Fig. 6

Fig. 7

Fig. 8

INSTALLATION OF FORK LEGS:

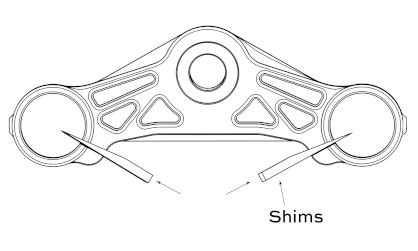

IMPORTANT! Not using shims can potentially cause damage or scoring to forks.

- Before installing forks into either Kraus tree, use spreader/shims to open the bore of each tree. (See fig. 9)

- Install each fork leg into trees. (See fig. 10) Ensure pinch bolts are loose. Starting with one side of the triple tree using small flat blade screwdrivers or shims, expand both top and bottom fork clamp pinch bolts slightly. This makes sliding the fork into the triple trees easier, while avoiding damaging the fork legs. Repeat process with opposite side.

- Make sure right and left forks are in their proper position. Riders right side fork is Rebound, left side fork is compression.

- Slide each fork leg upwards into triple trees clamps; avoid scratching the fork tubes. Ensure top triple tree does not lift off the dust shield.

- Adjust the fork tube height in the triple trees so that just the fork cap is protruding above the top triple tree. Push down on top triple tree to make sure the top triple tree has positive contact with the top neck bearing dust shield. Set both forks equal height in triple trees, confirm alignment by sliding the axle into the slider bottoms.

- Make sure axial alignment is correct for proper fork and upper tube clearance.

- Torque bottom Tree pinch screws to 12ft-lbs. Wait until fall away has been set before torquing top tree clamping screws and top nut clamp.

Note: Wheel and axle MUST be installed before setting Fall Away.

Torque Specs:

- Bottom tree pinch screws: 12ft-lbs.

Fig. 9

Fig. 10

INSTALLATION OF AXLE:

- Prepare axle for install by lightly coating the surfaces of the axle with anti-seize or grease.

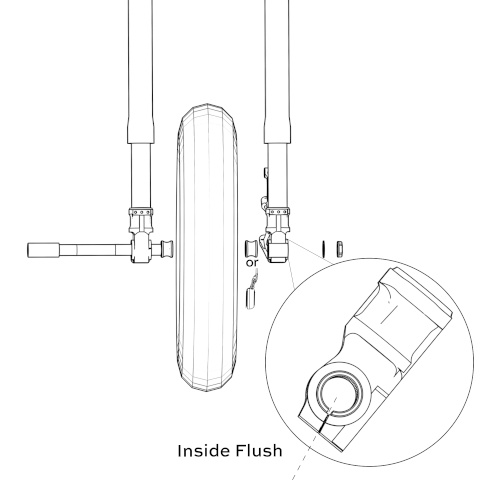

- Slide the axle through the Rebound fork starting with the smaller end. Axle will slide through fork, then wheel, then spacer, then other fork on the other side of the wheel. If your bike does not have ABS, use supplied spacer in this position. Slotted spacer is to be installed flush with the inside of the compression fork. (See fig. 11)

NOTE: Slotted spacer should have slit aligned with bottom slit of fork.

- Slide washer onto end of axle, thread nut onto front axle and torque with pinch bolts loose on bottom of forks (110ft-lbs).

- Torque pinch bolts. (19Nm/170in-lbs)

- With wheel installed, fall away can be set so long as NO additional components interfere with the swing of the front wheel, left to right.

- Mount calipers onto the KRAUS fork lower leg caliper receivers using M10x1.25 bolts. Brake pads must be properly aligned and have full contact potential with rotor friction area. Add caliper mount spacers depending on rotor size.

- Carefully and slowly rotate wheel making sure there are no alignment and clearance issues.

- Install front fender using supplied bolts and black delron spacers. Place the spacers between the fender and the forks. The longer spacers are to be installed in the rear fender mounts. (2013 and earlier model bikes will only have spacers on the rear fender mounts.)

- Again carefully and slowly rotate wheel making sure there are no alignment and clearance issues.

Torque Specs:

- Axle nut: 110ft-lbs.

- Pinch bolts: 19Nm/170in-lbs.

Fig. 11

Setting Fall Away:

- When setting fall away it is important not to use Harley’s Fall Away setting (B). Instead, use the Kraus fall away (A) referenced in Schematic 3.

- Raise the motorcycle so that the front and rear tires are the same distance from the floor.

- Turn the front wheel to the left Fork stop and then let go. The wheel should swing from side to side, finally stopping in the swing specified in schematic 3. If it stops in the lesser number swing it should be at or after the straight-forward position.

- Make sure the clutch cable or main harness is not influencing the swing momentum in any way.

- A steering head that is too tight can interfere with the vehicle’s ability to absorb a weave. A steering head that is too loose can interfere with the vehicle’s ability to absorb a wobble.

- With fall away set, top tree and clamp nut screws can be torqued to spec: (20ft-lbs).

- When installing your brake line, confirm brake lines are proper length and not stressed or stretched whether the front end is compressed or extended.

- Once the front end is installed and tightened up to specifications, you are ready to reinstall all of the components that you removed including any associated bodywork or accessories. We recommend that you refer to your OEM manual for procedure, step by step run through, required tools and specifications.

- After all pieces and parts are properly installed, go for a slow, careful test ride. Afterwords, double check all pieces, parts and systems.

SCHEMATIC 3

STEP 3 - FINISHING UP THE INSTALLATION:

CUT TEMPLATES:

Road King

- The Road King Nacelle must be cut to fit over the edge of the tree.

Road Glide

- The Road Glide Nacelle may be left uncut if the fork adjuster is installed flush with the top of the top tree.

- Kraus recommends still cutting the nacelle as it allows for adjustment.

- Drilling a hole into the nacelle is recommend as it allows for easier adjustment and service for the fork, i.e., adjusting your preload, compression, and rebound setting.

NOTE: We recommend that you refer to your OEM manual for procedure, step by step run through, required tools and specifications to make sure all pieces and parts are properly installed! Go for a slow, careful test ride. Afterwords, double check all pieces, parts and systems.